METAL POWDER MATERIAL

316L Stainless Steel

316L stainless steel (grade: 00Cr17Ni14o2) with main alloy element of Cr, Ni, Mo, national standard: GB/T 20878-2007. As a typical widely known stainless steel, it has excellent corrosion resistance, heat resistance and creep resistance, extensively applied in food industry, chemical industry, mechanical parts, marine equipment, small industrial parts, complex pipes as well as artifacts.

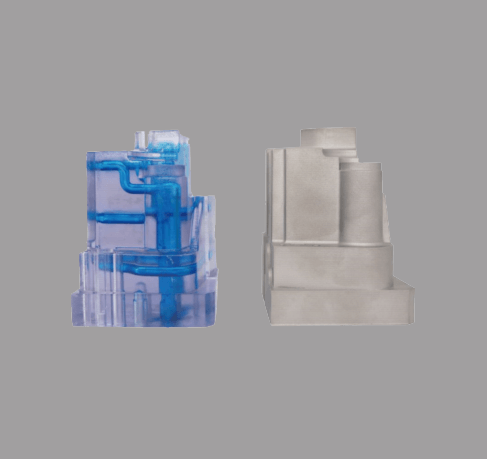

MS1 Mold Steel

The corresponding grade of the MS1 mold steel is US 18% Ni Maraging 300, the European grade is 1.2709, the German grade is X3NiCoMoTi 18-9-5, and the Chinese grade is 00Ni18Co9Mo5TiAl. This steel grade has some unique properties: high strength and toughness, low hardening index, good formability and good welding performance. After simple heat treatment, it achieves ultra high strength and hardness, suitable for mechanical parts, precision forging dies and plastic mold.

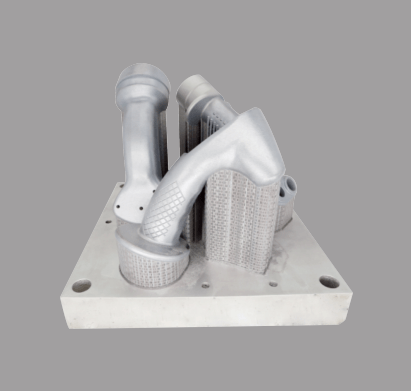

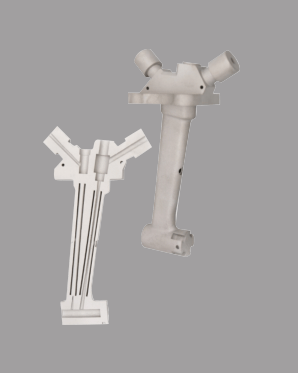

AlSi10Mg Aluminum Alloy

As casting aluminum alloy, ingredients similar to YL104, national standard: GB/T 15115- 2009, it has good casting performance, hot workability and light weight, low hot crack and cold crack tendency advantages, widely used for rapid prototyping complex automotive parts, industrial parts, aerospace components, machinery, petrochemical, electromechanical parts.

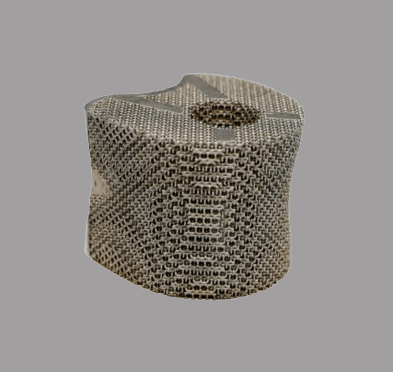

TC4 Titanium Alloy

The composition of TC4 alloy is Ti-6Al-4V, which belongs to (α + β) type titanium alloy, and the national standard is GB / T 3620.1-2016. As a typical titanium alloy, TC4 has a series of advantages such as excellent corrosion resistance, light density, high specific strength, good weldability, and good biocompatibility. This alloy can be widely used in 3D rapid prototyping for aerospace, petrochemical, marine, automotive, medical implant and other fields.

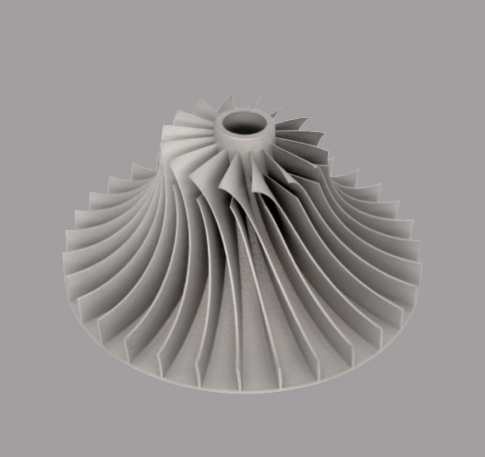

IN718 Nickel Base Alloy

IN718 is a precipitation strengthened nickel-based alloy containing niobium and molybdenum, and the corresponding grades are GH4169, GH169 (China), NC19FeNb (France), NiCr19Fe19Nb5, Mo3 (Germany), NA51 (UK), Inconel718, UNS NO7718 (USA) , NiCr19Nb5Mo3 (ISO). These alloys have good tensile, fatigue, creep, fracture strength, high oxidation resistance.and corrosion resistance at high temperatures, and stable chemical properties at low temperatures. It can be widely used in high-temperature parts, such as: gas turbine parts, aero-engine parts, instrument parts, power engineering parts and some manufacturing industrial parts, and 3D rapid prototyping of low-temperature application parts.